CERTIFIED QUALITY AND RESPECT FOR TRADITION

: 01/07/2020

AN ACCURATE AND CONSTANT CONTROL

Through a careful and constant control during the entire production process, Agriform products ensure the application of standards that are even stricter than those required by the specifications and in full respect of hygiene criteria.

MATURING: A PATH TO EXCELLENCE

The maturing and refining warehouses are perfectly insulated and equipped with sophisticated air conditioning systems for the maintenance of humidity and temperatures, suitable for the seasoning and refinement of all specialties that require a particular aging.

Maturing, which can last from a few weeks and extend to over two years, is done respecting the minimum scheduled times for the turning-over and cleaning of the wheels, and includes strict quality controls during the entire process. In order to determine the consistency and homogeneity of the interior of the cheese, the wheels are tapped one by one and are then branded or selected to continue ageing and become part of the Oro del Tempo selection.

Maturing, which can last from a few weeks and extend to over two years, is done respecting the minimum scheduled times for the turning-over and cleaning of the wheels, and includes strict quality controls during the entire process. In order to determine the consistency and homogeneity of the interior of the cheese, the wheels are tapped one by one and are then branded or selected to continue ageing and become part of the Oro del Tempo selection.

PACKAGING: INNOVATION AND CONVENIENCE

The portioning and packaging centres are equipped with state-of-the-art technologies for the perfect hygienic and organoleptic storage of the cheeses. The center of Sommacampagna, divided into two separate areas, is equipped with the latest automated machines which meet the most stringent hygiene-health standards required for food facilities by HACCP analysis and by international quality standards. In particular, all packaging lines are controlled by metal detectors.

PORTIONS WITH RIND DEPARTMENT

The department for portion cutting and packaging is made up of 8 lines. Two lines for packing in vacuum bags: the first one portions the wheels into quarters and eighths; the high speed second line is for the making of pieces from approximately 150 g to 2 kg.

Two lines thermoforming lines for the packaging of Grana Padano, Asiago and other cheeses in vacuum packs (flexible) or in a protective atmosphere (rigid plastic tubs).

Two horizontal lines for the flow-pack packaging in protective atmosphere of semi-hard cheese slices (Asiago and Piave).

A line for the packaging of Grana Padano wedges in heat shrink film.

The last line, equipped with high-tech automation systems, is dedicated to the packaging of Gira&Gratta.

Two horizontal lines for the flow-pack packaging in protective atmosphere of semi-hard cheese slices (Asiago and Piave).

A line for the packaging of Grana Padano wedges in heat shrink film.

The last line, equipped with high-tech automation systems, is dedicated to the packaging of Gira&Gratta.

GRATING AND OTHER PORTIONS WITHOUT RIND DEPARTMENT

The grating department is made up of five lines. This is where the product is packaged in a protective atmosphere inside heat-sealed bags which are able to maintain the product’s moisture, fragrance and freshness. The production line starts with whole, clean and scraped wheels which are grated and are then packaged in polyester and polythene bags; besides grating, these packaging lines also package other formats without the rind: cubes and slivers; Two additional lines are dedicated to the packaging of small blocks in protected atmosphere bags and cubes in thermoformed tubs.

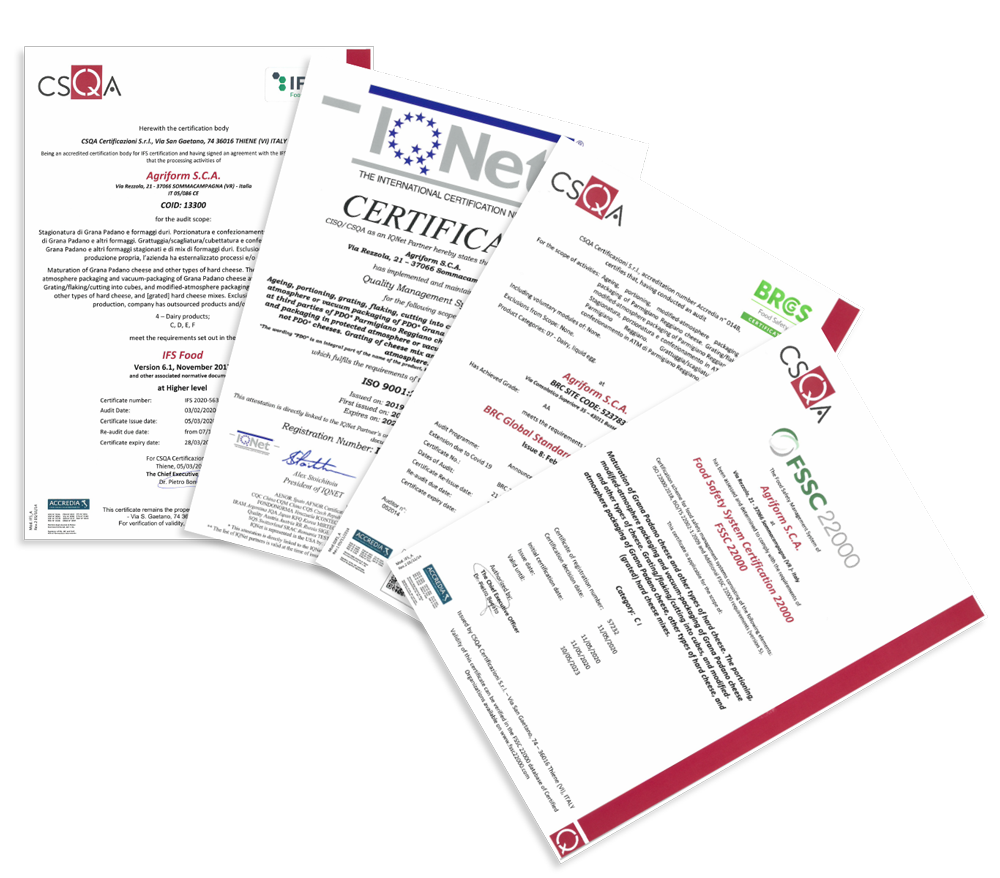

QUALITY AND FOOD SAFETY CERTIFICATIONS

The commitment to quality is confirmed by the attaining of important certifications issued by authorities:

For the quality management system of the company’s processes..

For quality in ageing and packaging of Grana Padano PDO, the packaging of PDO cheeses and other typical Italian cheeses and mixes of aged grated cheeses. Standard developed by German (HDE) and French retailer organisations (FCD).

An integral part of the Quality System is the management plan following the HACCP methodology (hygienic self-checking method designed to product consumer health) regarding the logistical process of ageing and packaging.